EVERDURE CALTITE for Marine, Salt & Acidic Environments & Corrosion Protection

- Prevention of Disintegration of Concrete through attack by Sulphate/Chloride Soluble Salts, and also specialised construction applications.

- Membrane-free Waterproof Concrete Structures

- The EVERDURE CALTITE SYSTEM is a time-proven, practical system which produces effectively non-absorbent, impermeable and durable field concrete. It completely eliminates the need for membranes or other temporary methods of waterproofing.EVERDURE CALTITE has a successful track record of more than 38 years of helping designers and owners protect concrete structures, even under the most severe conditions.

EVERDURE CALTITE concrete is used for:

SALT & MARINE ENVIRONMENTS

Concrete Sucks – it is absorptive, that’s why it corrodes.

The Everdure Caltite concrete is non-absorptive. Caltite concrete will not absorb water and contained salts, and so is immune to chlorides and corrosion from marine environments.

ACIDIC ENVIRONMENTS

Protection of foundations and other concrete from disintegration by acids and acidic groundwater is vital to ensure the long-term performance of the structure. The EVERDURE CALTITE system is the practical way to protect concrete against acid attack. Unlike coatings or membranes, EVERDURE CALTITE is not susceptible to discontinuities or mechanical damage as it protects throughout the concrete mass.

INDUSTRIAL FLOORS

Protection of structural concrete for industrial floors exposed to aggressive chemical attack is vital for their profitable operation. Such attack results in pitted, uneven and eventually structurally unsound floors that require continued maintenance. Everdure Caltite concrete protects floors used for storage of fertilisers, sugar, salt etc.; manufacture of aggressive chemicals; processing of palm oil and rubber; animal husbandry and processing and storage of food stuffs.

EVERDURE CALTITE – Over 30 Year Proven Performance

in Salt & Marine Environments

Premature deterioration of concrete structures caused by chloride-induced corrosion is the most serious problem facing the construction industry. Concrete exposed to a marine environment, airborne salt and de-icing salts are all at risk.

Ordinary absorptive concrete and traditional protective measures have not provided adequate durability under actual field conditions. The primary problem is the absorption of salt water into the concrete matrix resulting in an accumulation of salts.

The EVERDURE CALTITE System makes concrete non-absorptive and impervious to water and contained salts. In this way, EVERDURE CALTITE provides a time proven system for the protection of concrete in salt and marine environments with a track record of 38 years.

1962: Field trials were conducted by the Engineering and Water Supply Department in tidal salt pans in the desert regions of Southern Australia. Soil analysis showed very high levels of chloride and sulphate salts. These were found to cause rapid deterioration. After 30 years exposure in sabkha salt pan, EVERDURE CALTITE concrete has remained virtually unaffected. Otherwise similar ordinary Portland and sulphate-resisting cement concretes have all but disintegrated.

l965: A reinforced concrete boat ramp was placed in two sections; one with and one without EVERDURE CALTITE.

The control concrete showed severe aggregate exposure as well as widespread cracking due to corrosion of reinforcement. The EVERDURE CALTITE section was found to be in excellent condition with no corrosion of reinforcement and no noticeable surface wear.

1982: Concrete beams with and without EVERDURE CALTITE were suspended beneath a wharf in Western Australia to determine their relative durability. After more than 5 years of continual wetting and drying with sea water, cores were taken and chloride penetration measured.

In spite of cement contents of 400kg/m³, water/cement ratios of 0.4 and good curing before exposure, there had been significant chloride penetration into the control concretes. EVERDURE CALTITE was found to greatly reduce the quantity and depth of chloride penetration in spite of having received inferior curing than the control.

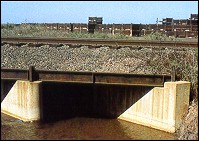

The rail bridge passes over the slag quenching pit salt water return channel. After more than 20 years exposure to this very severe environment, the EVERDURE CALTITE concrete is in excellent condition.

By 1976, this dry dock had become severely deteriorated. EVERDURE CALTITE was used in the replacement concrete to ensure long term performance under such severe conditions.

EVERDURE CALTITE concrete jacket around salt damaged bridge support. Morningside Bridge, Toronto, Canada.

EVERDURE CALTITE – Over 30 Year Proven Performance

in Acidic Environments

Protection of foundations and other concrete from disintegration by acids and acidic groundwater is vital to ensure the long-term performance of the structure. If acid attack occurs to foundations, it may remain undetected until serious damage is incurred and would be very difficult to repair.

The EVERDURE CALTITE System has been shown to be the practical way to protect concrete against acid attack. Unlike coatings or membranes, EVERDURE CALTITE, is not susceptible to discontinuities or mechanical damage as it protects throughout the concrete mass.

However, under conditions of extreme acid exposure, we do recommend that appropriate surface coatings should be used in conjunction with EVERDURE CALTITE to protect against attack of the external surface.

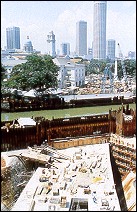

This tunnel section of the Mass Rapid Transit System beneath the Singapore River was protected with EVERDURE CALTITE. This concrete was exposed to both a marine environment and the pH of the adjacent soil was found to be as low as 2.8.

The rail bridge passes over the slag quenching pit salt water return channel. After more than 20 years exposure to this very severe environment, the EVERDURE CALTITE concrete is in excellent condition.

EVERDURE CALTITE – Over 30 Year Proven Performance

in Industrial Flooring

The floor of a factory, chemical storage or production facility is a key component in its profitability. Premature deterioration of the floor slab involves great costs in terms of repair and down-time. EVERDURE CALTITE effectively dampproofs and corrosion proofs concrete slabs without the need for external layers which so often fail. EVERDURE CALTITE also provides a hygienic, durable floor which is most suitable for many industrial, agricultural and food processing applications.

Many fertilisers are not only highly aggressive but also very hygroscopic, (i.e. they rapidly absorb any moisture available to them). Therefore, the floor for a fertiliser plant must not only be durable but also dampproof. EVERDURE CALTITE provides both durability and dampproofing in one system. The benefits and savings are enormous. In the floor opposite, the single, impermeable EVERDURE CALTITE slab was considerably less expensive than the conventional “sandwich construction” originally considered.

Concrete floors used for food processing and storage, markets, abattoirs and housing livestock should be designed and built to provide an easy-to-use, hygienic floor which requires a minimum of maintenance.

When exposed to food, blood, urine, faeces and the by-products of bacterial decay, ordinary concrete is subject to severe and rapid chemical and physical attack.

EVERDURE CALTITE has proven to be well suited in these applications, resisting even the most severe conditions, and remaining hard wearing and hygenic.

The bulk storage fertiliser terminal (above) was built in 1972 using EVERDURE CALTITE to dampproof and protect the floor. After 19 years operation, the floor is still in excellent condition in spite of exposure to urea, ammonium nitrate etc

The above picture shows a sugar refinery with an EVERDURE CALTITE concrete floor coated with an epoxy for ease of cleaning.